Washer Formula History Report

Overview

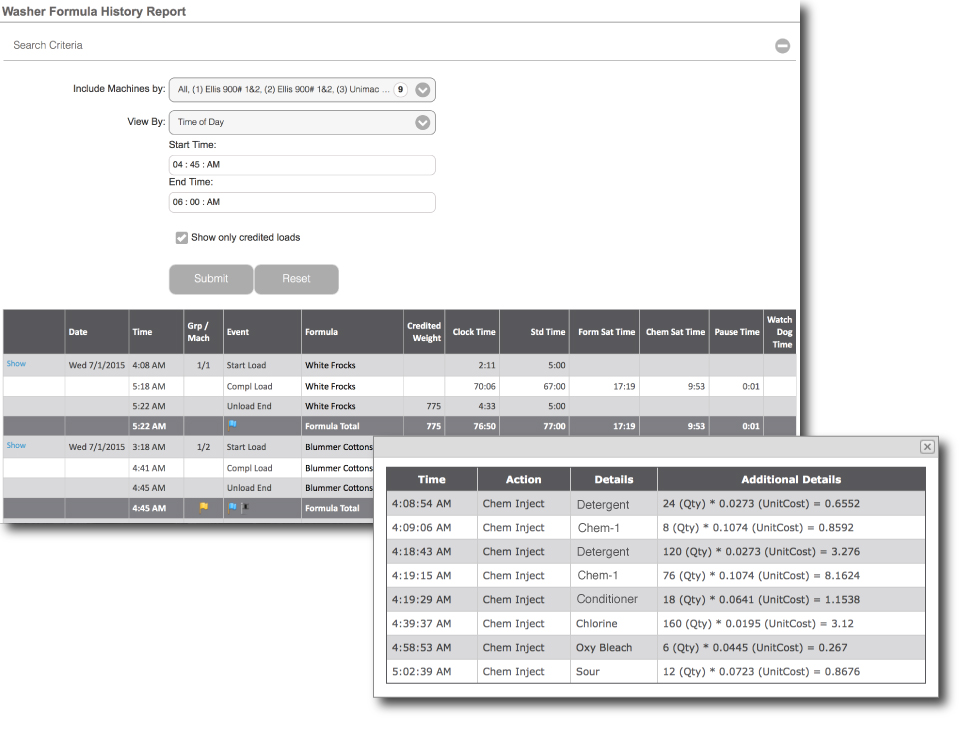

The Washer Formula History Report provides you with detailed information about your formulas for the selected dates. The report gives a detailed comparison of formula events compared to the standards on a load-by-load basis. The report contains information on chemical injections, password actions, and watchdog resets.

The resulting report includes four rows for each formula ran. This first three rows of data include load, unload, and completion details. The fourth row (darker gray) provides summary and totals for the formula run. Clicking the "Show" link in the first column brings up chemical-specific information for the formula.

Example Report

The Washer Formula History Report showing the criteria section. To generate the smaller detail table, click the "Show" link in the first column.

Glossary

Report Criteria

Report Dates:

The report uses the date selections from the Report Dates selection tool. Access the Report Dates selection tool on the left-side menu or click the calendar icon at the top of the screen on handheld devices.

Include Machines:

Get formula histories for a single or a combination of machines using the Include Machines drop-down.

View By Shift or Time

Fine-tune your data for a particular shift or time of day or leave the default to get the entire day.

Show Only Credited Loads

Check the Show Only Credited Loads checkbox if you want to exclude formulas that didn't complete.

Result Set

The resulting table contains four rows for each formula ran. The darker gray row serves as a summary of the formula and marks the end of that entry.

Details

Clicking the "Details" link allows you to view additional formula event information.

Grp/Mach (Group/Machine)

The group number with machine number.

Event

Three primary events that constitute a formula: load, complete, unload. The results also include incomplete statuses if you select non-credited loads in the criteria section.

Formula

The name of the formula.

Credited Weight

The weight credited to your production totals. The automated rail system provides this value, or the operator manually enters the weight.

Clock Time

The amount of time it took the event to complete including any hold times (e.g., waiting for the water temperature to rise).

Std Time (Standard Time)

The expected duration of the event.

Form Sat Time (Formula Satisfy Time)

The time in minutes and seconds that accumulated while the formula waited for machine events to complete. For example, the collective time for the washer to fill with water, or drain to a particular level. The Formula Satisfy Time includes the Chemical Satisfy Time.

Chem Sat Time (Chemical Satisfy Time)

The time in minutes and seconds that accumulated while the machine received chemical injections.

Pause Time

The time in minutes and seconds that the machine waited in pause mode while the operator completed a task that enabled the formula to proceed (e.g., add dye).

Watchdog Time

The time in minutes and seconds that elapsed while the machine waited for the operator to respond to an error condition.

Summary Row

The summary row (darker gray) contains your totals for the formula and any formula flags.

Flags

The system flags formulas based on the selections in the Washer Settings. You may see the following flags:

Canceled Loads – Loads canceled by the operator.

Loads with watchdog time – Loads that had alerts that went unattended longer than a specified amount of time.

Run time flag – Loads that complete above or under a specified run time.

Load time flag – Loads where the load time exceeded or fell short of the standard load time.

Unload time flag – Loads where the unload time exceeded or fell short of the standard unload time.